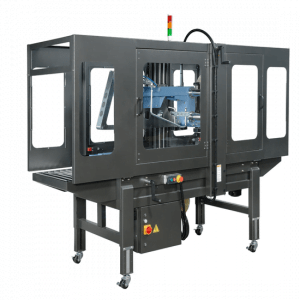

Description

Standard Features

- Left-in and right-out machine or vice versa are available

- Fixed sleeve magazine change part

- Sleeve magazine with auxiliary pneumatic agitation for sleeve pick-up

- Patented rotary sleeve feeder. Pickers always face outwards thus no collision in the sleeve

- Servo-driven overhead belts can be levered for maintenance

- Focke Meler B4 hot melt jetting system

- SIEMENS Control Platform

- SINAMICS S7-1500 PLC

- SINAMICS V90 servo converter

- SIMOTICS S-1FL6 servo motor

- KTP 900 HMI Panel

- Speed up to 150 PPM according to container size and format

- Caster mounted for easy installation

- Ergonomic safety guards with hall switches for operator safety

- Emergency buttons available at all corners

- Robust stainless-steel construction for food-grade use

- Simple size changeover around 15 minutes

Optional Features

- At Additional Cost

- Powered and extended sleeve hopper

- Bespoke conveyor, grouping and infeed system (according to container shapes and sizes)

- Additional fixed sleeve magazine change part

- Ink coder or laser coder

- Nordson Mesa or Nordson Pro Blue Glue System

- Remote Access Devices for Support (Ewon Box, Inovance, Teltonika)

- Wash down to IP65 or NEMA 4X

Reviews

There are no reviews yet.